Handheld XRF Metal/Alloy/Stainless Steel Analyzer DW-EX5000

Packing Size:

Gross Weight:

Packing Material:Paper Carton

Liquid/Battery/Motor:No

HS Code:9027300090

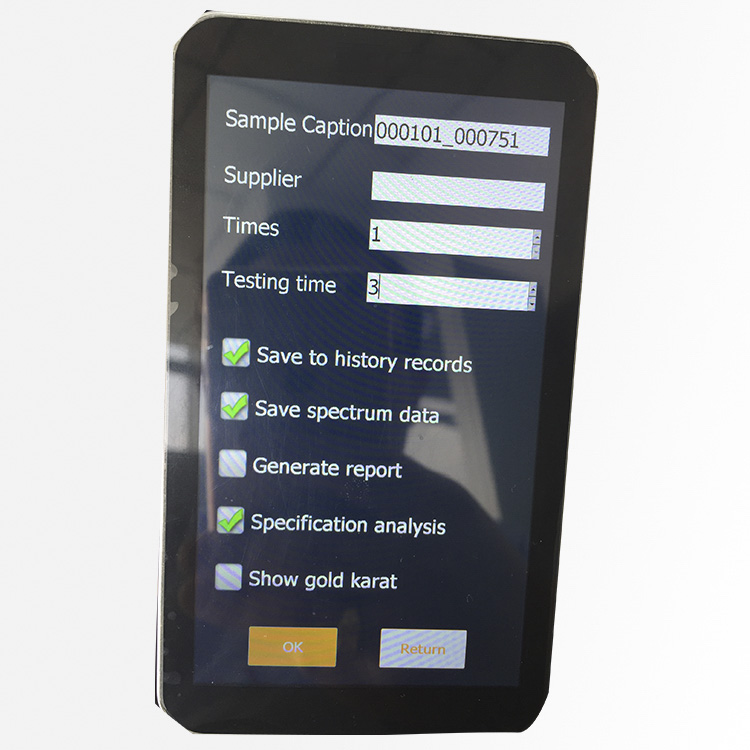

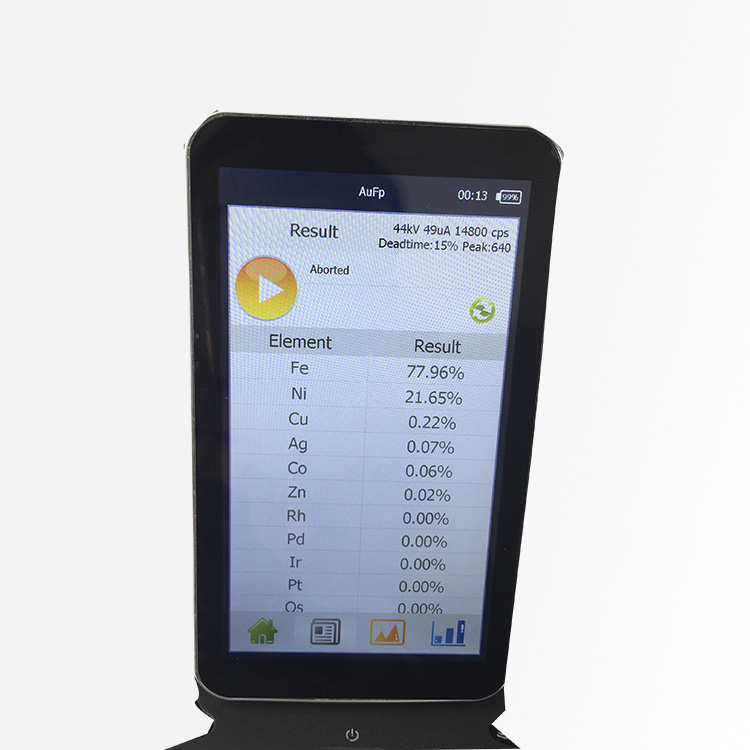

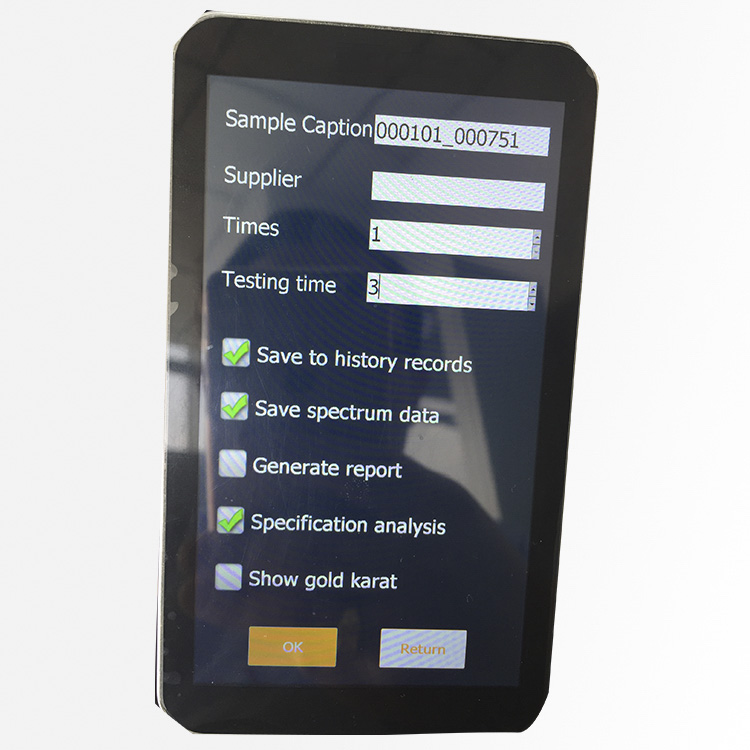

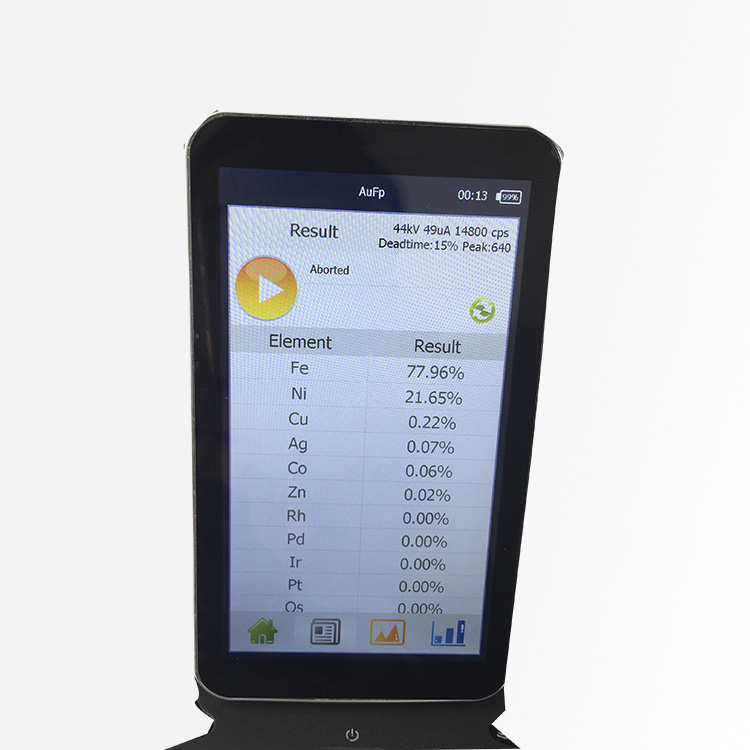

DW-EX5000 handheld XRF adopts Photoelectron, microelectronics, semiconductor, computer and many other technology and develop the new generation of handheld XRF with Independent Property Rights. DW-EX5000 andheld alloy analyzer uses large-screen, high-resolution LCD and the new digital signal processor. The minimum detection limits make its performance as great as the desktop. With small size and light weight, DW-EX5000 is portable for testing and suitable for analyzing different kinds of alloy.

Application Field

- Precious metal alloy

- Boiler pressure vessel

- Iron and steel smelting

- Aerospace industry

- Waste metal recycling

- Shipbuilding

- Machinery manufacturing and processing

DW-EX5000 can make accurate and nondestructive detection on a variety of precious metal alloys, low alloy steel, stainless steel, tool steel, chrome / molybdenum steel, nickel alloys, cobalt alloys, nickel / cobalt-resistant alloys, titanium, copper alloy, bronze, zinc alloy, tungsten alloy, etc. Knowing the materials composition and alloy kind in one second. Rapid detection on aluminum and magnesium alloy grades is possible and it allows to make reliable identification and confirmation of the material (PMI) and precisely control the materials quality.

●Reliable identification of materials

In the process of alloy materials production and machinery manufacturing and processing, elements detection can't work without the identification of materials. DW-EX5000 professional and nondestructive detection can effectively prevent the mix of raw material and avoid unnecessary loss.

●Quality control in industrial production

DW-EX5000 professional and nondestructive detection can be used for quality control and management in the manufacturing process of steel smelting, boiler industry and other high- temperature and high-pressure industries to ensure the materials quality; identification of alloy composition in shipbuilding, aerospace and other high-tech industries in order to ensure product quality and safety; identification on the quality of the spare parts in electric power plants and other industries related to people's livelihood to guarantee the equipment safety.

●Waste metals recycling and reuse

In waste metal recycling and reuse industry, EXPLORER 5000 can make on-site detection and rapid classification of scrap metals; recycle overstocked steel in the warehouse; classify metals in salvage station; recycle the turning scraps and cuttings. If s a powerful tool to make metal and steel identification in waste metals recycling industry.