1400℃ STD series Industrial Box Furnace

Packing Size:

Gross Weight:

Packing Material: Wooden Case

Liquid/Battery/Motor:No

HS Code:8514199000

Introduction

1400°C industrial furnace (box type resistance furnace) mainly provides high temperature heat treatment environment for industrial, research institutes, factories and other industrial laboratories, and is applied to new materials such as metal materials, ceramic materials, nano materials, and semiconductor materials.

Features

Furnace shell

1.High quality Q235 low carbon steel, corrosion resistant,CNC processing.

2.Sturdy metal frame shell structure, low surface temperature, safe to use.

3.Side-opening door structure, the door opens to the right, easy to operate.

4.Energy efficient insulation keeps exterior safe to touch.

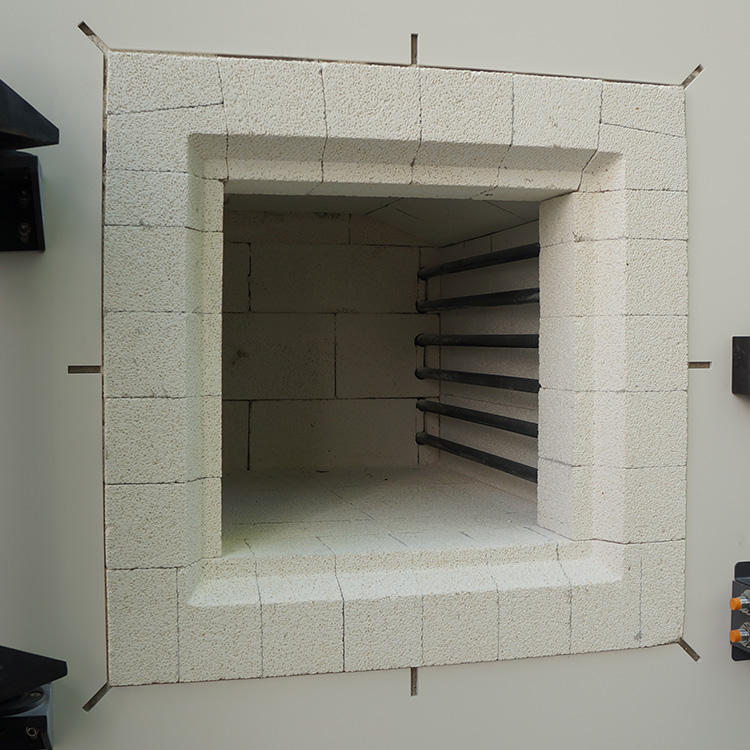

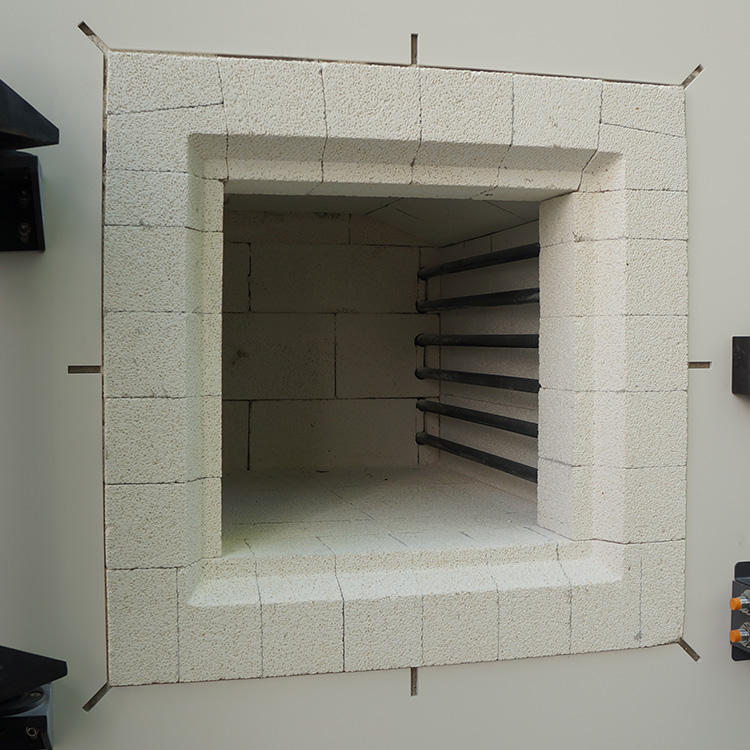

Chamber material

1.Furnace Lining: Furnace material is 1400℃ high-purity Light Mullite bricks.

2.Thermal Insulation Material: The furnace is insulated by polycrystalline alumina ceramic fibers with temperature resistance of 1260℃.

3.Adopt high quality alumina polycrystalline fiber with good insulation and durability properties.

4.Vertical heating elements evenly distributes on two sides of the chamber which give an ideal temperature uniformity.

Heating System

1.High quality SIC heaters, safely and securely installed on both sides of the furnace chamber, free thermal radiation heating in the furnace cavity, energy efficient.

2.Two-side heating (left and right sides) to realize the good uniformity in the furnace.

3.Silicon carbide base plate covers and protects the bottom heating element, with high mechanical strength and good thermal conductivity, and also provides horizontal bearing.

Temperature controller

1.High quality HRE alloy resistance wire,Excellent temperature uniformity.

2.Control system integrated in the furnace base, Defined application within the constraints of the operating instructions.

3.LED displays the actual temperature v.s the setting parameters.

4.Intelligent microcomputer PID controller can program 30 segments.

Safety precautions

1.Overheating & Broken thermocouple protection.

2.Leakage circuit breaker.

3.3. Automatic power off when furnace door opens (optional function).

4.4. Over-temperature protection and alarm allow for operation without attendant(s).

5.5. Microprocessor-based PID control with self-tuning capability to prevent overshooting of set temperature.