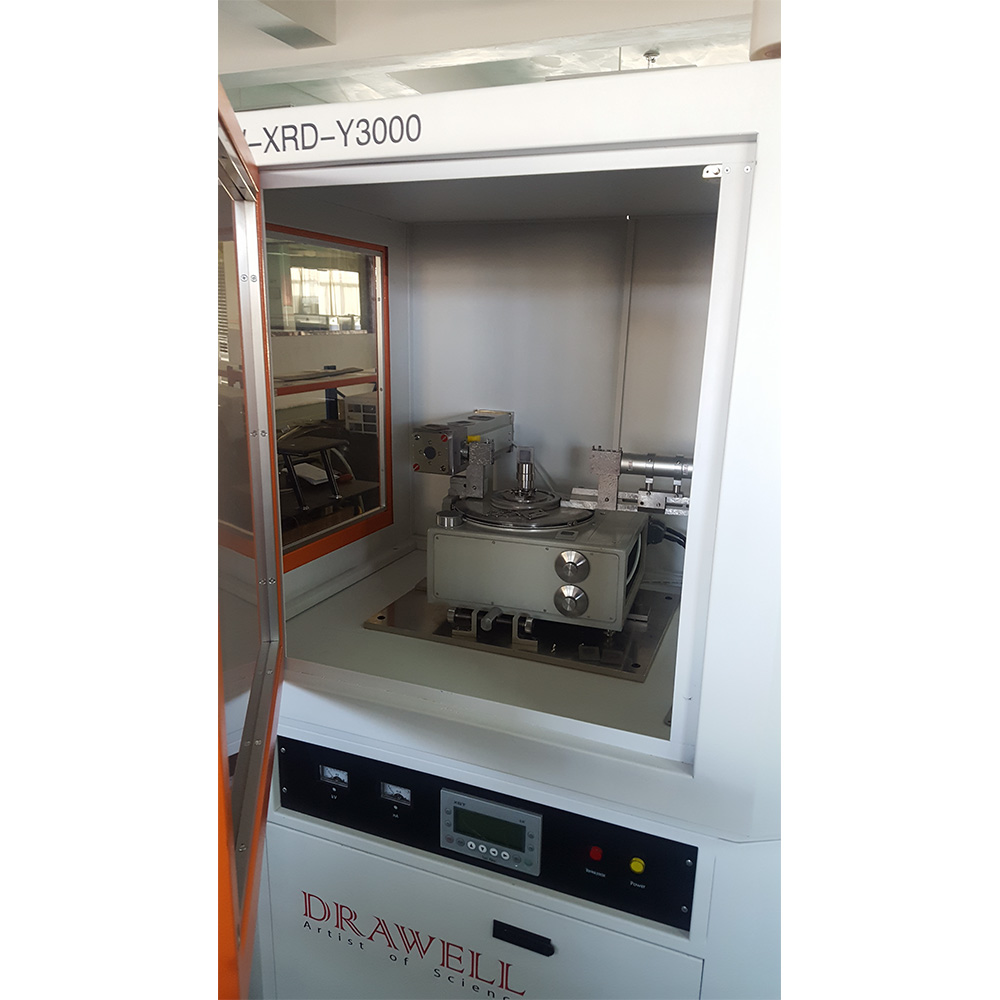

DW-Y3000 XRD Technical Solution

Packing Size:

Gross Weight:

Packing Material:Wooden Case

Liquid/Battery/Motor:Yes

HS Code:9022199020

Brief:

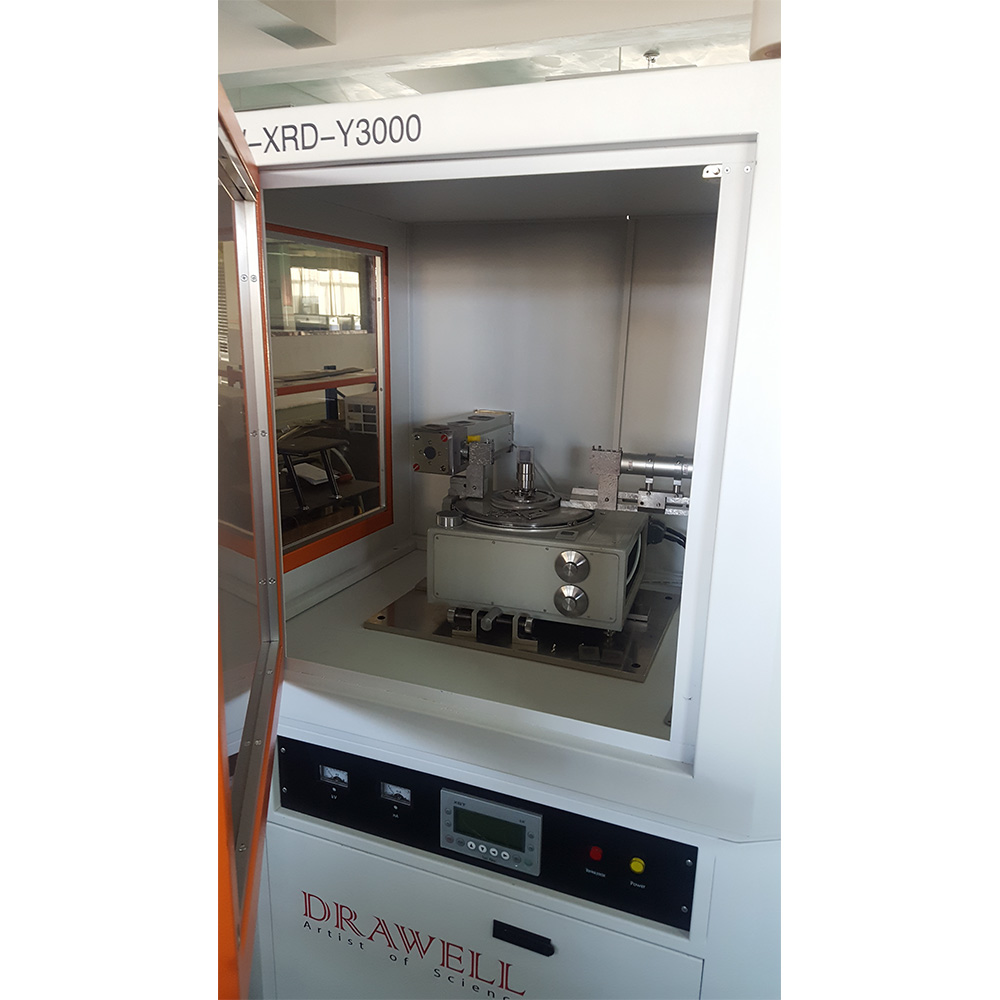

X-ray diffractometer(XRD) is a widely used large analysis instruments in internal structure of the material studying. It can accurately determine the crystal structure, lattice constant, and complete material qualitative or quantitative analysis. By installing some accessories it can realize structure, macroscopic stress or micro stress determination, crystal size and degree of crystallinity determination, etc.The perfect combination of hardware and software can meet the

needs of scholars and researchers in different application fields.

Our advantages

More accurate:Have the high precision goniometer system and the highly stable X-ray generator control system.

More convenient :Programmed operation, integrated structure design, simple operation, and more beautiful instrument appearance.

More stable:It adopts imported PLC control technology, has high degree of automation, low failure rate, long using life.

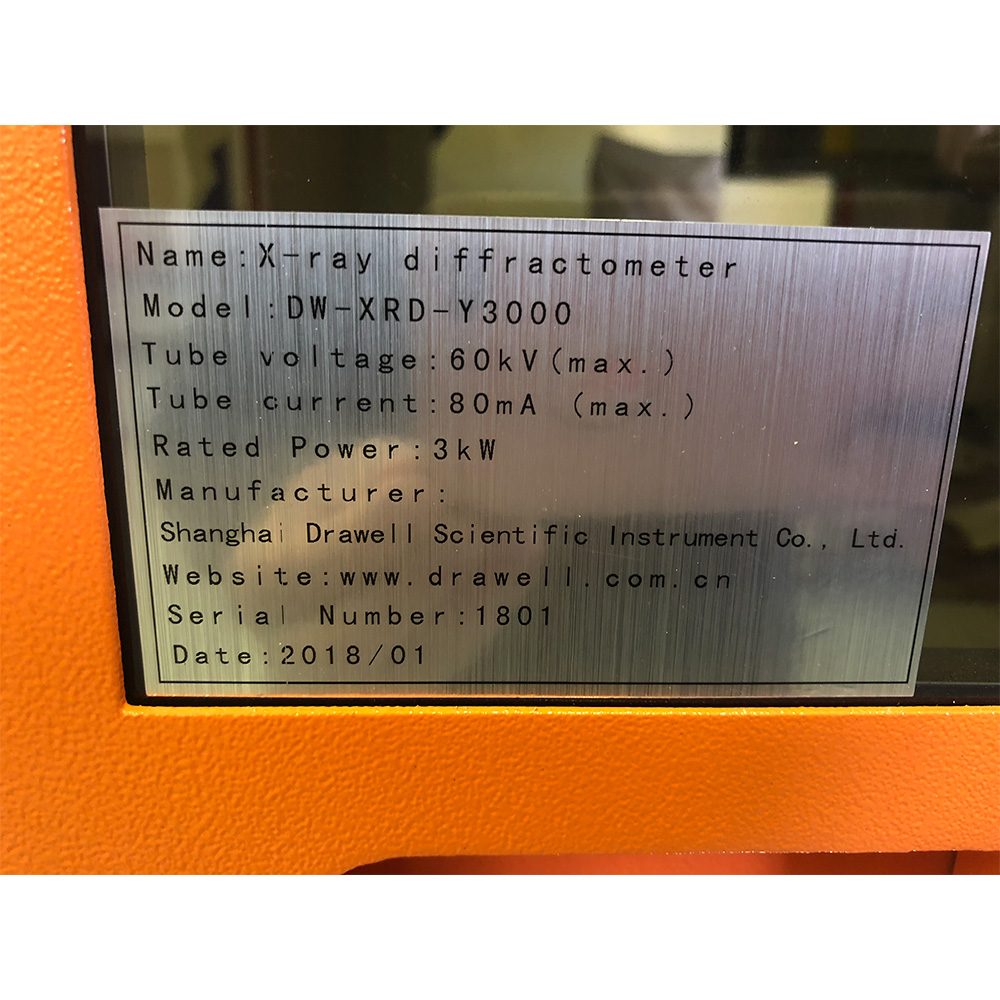

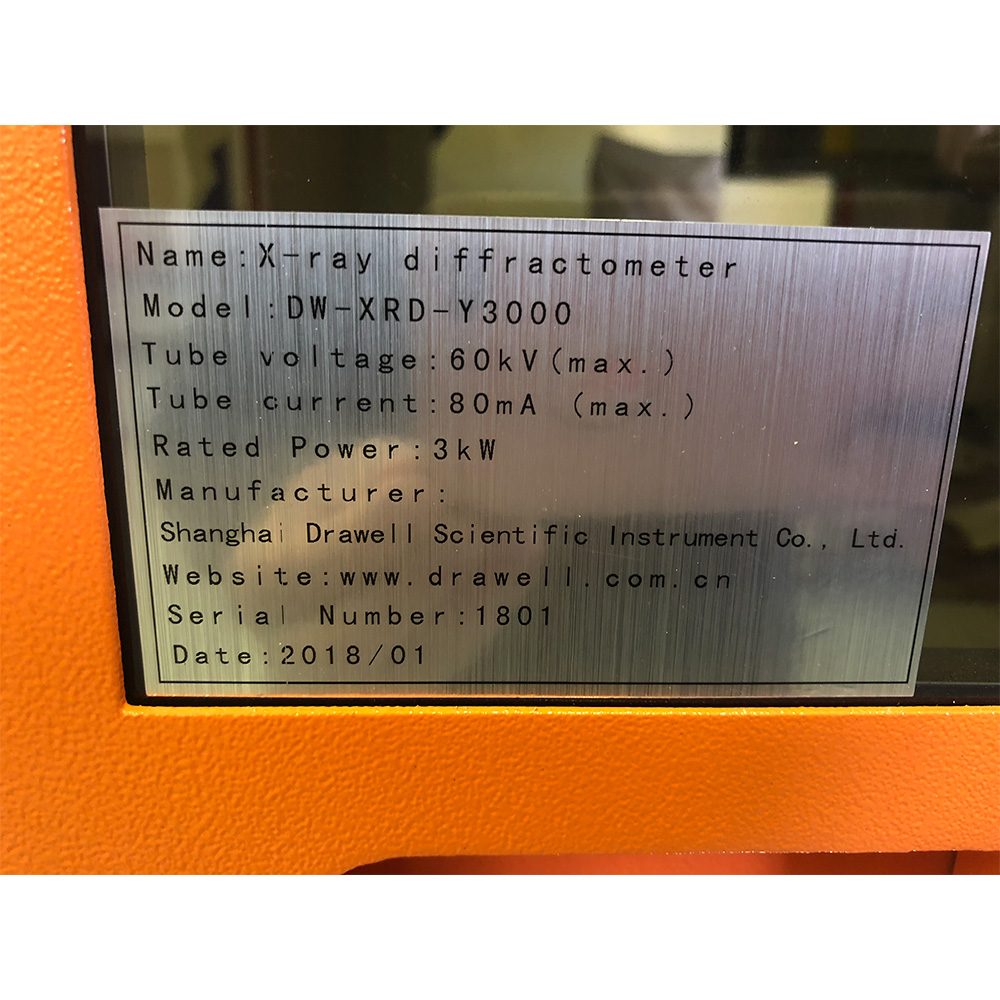

DW-3000 XRD Property and Technical Parameter

1. High pressure generator(Adopting imported PLC control technology):

*Rated Power:3kW;

*Tube Voltage:10~60kV It is automatically controlled by computer terminal(1kV/step);

*Tube Current:5~80mA It is automatically controlled by computer terminal(1mA/step);

*Tube Voltage and Current Stability≤0.01%;

*Protection of over voltage, over current, over power, and low water level;

*X-Ray Tube:Cu target、Focal point 1×10mm2、Power 2.0kW;

*Optical shutter switch is automatically controlled by computer terminal;

*Unibody structure cooling device, Cooling device is unibody structure, and the automatic temperature control system can indicate the water temperature of X-ray tube.

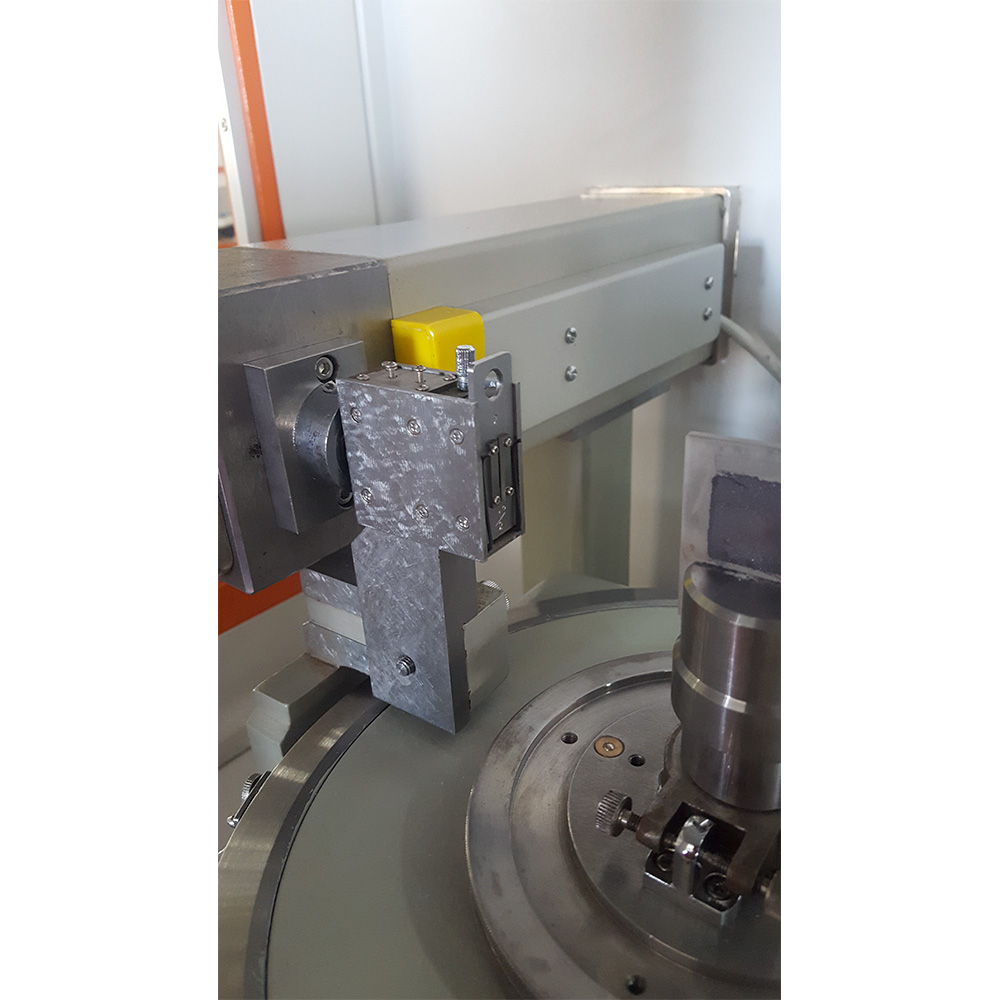

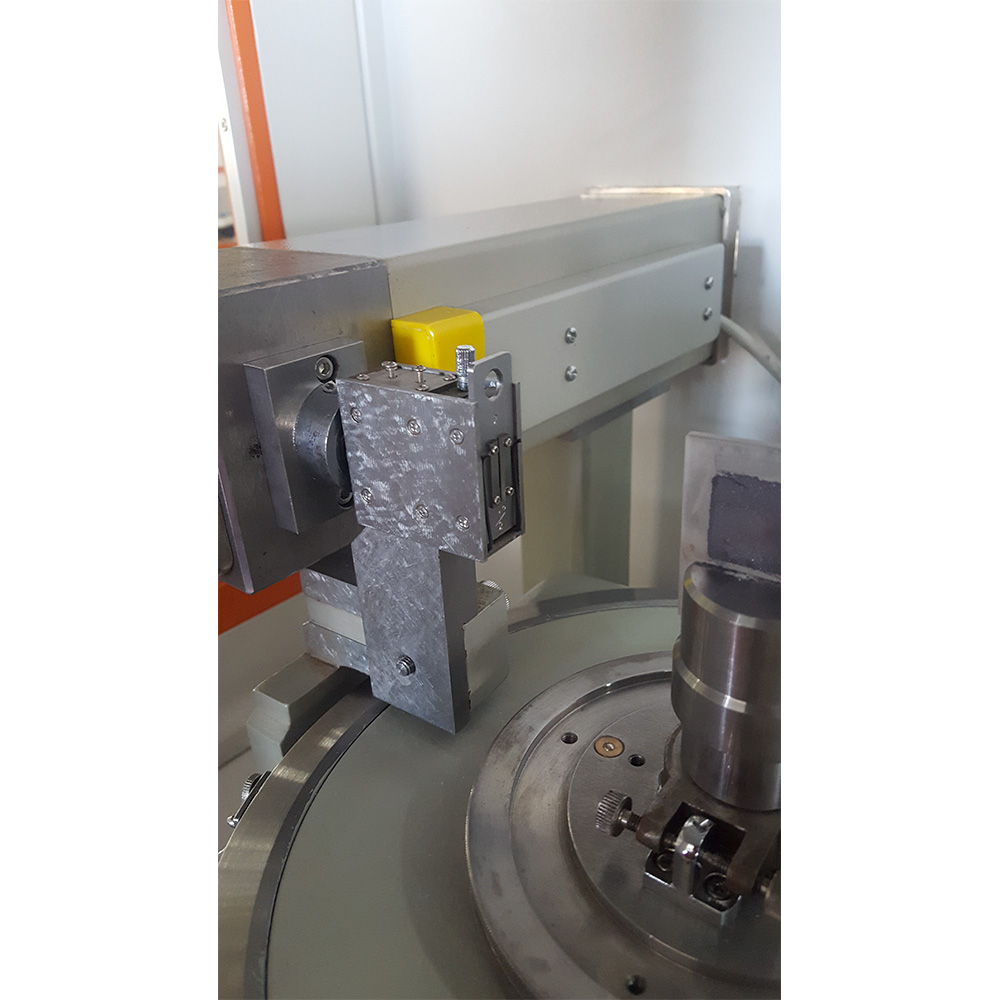

2. Goniometer and Control (Horizontal type):

*Horizontal Type θ—2θ, diffraction circle radius 185mm; Rotation of goniometer is

controlled by stepping motor (forward or reverse, forward scan), drive mode (move individually or jointly ), scanning mode(continuous, stepping), scanning speed, it can do angle-auto correction, detect losing step and avoid lost motion;

*Minimum Step Angle: 0.001°

*Continues Scan Speed: 0.0012°-70°min

*Step scanning step width angle: 0.005~165°

*2θAngle measurement range:≤0.005°;

*2θAngle measurement range:0--164°

*Goniometer 2θangle uni-directional Repeatability 0.001°

3. Recording and Controlling Unit and Detector:

*Closed scintillation counter

*Auto differential and integral conversion

*Base line and channel width: 0%~99%

*Continuous adjustable high voltage of detector : 0~2000V

*High voltage stability of detector: ≤0.01%

*Optional X-ray tube target material: Cr、Fe、Co、Cu、Mo

*Energy Spectrum Analysis (Cu,Kα Curve): ≤25%(PC),≤50%(SC)

4. Overall Stability

System overall stability ≤0.3%;

5. Outline Dimension

XRD host net Dimension:1100×950×1750mm

6. X-ray protection up to national standard

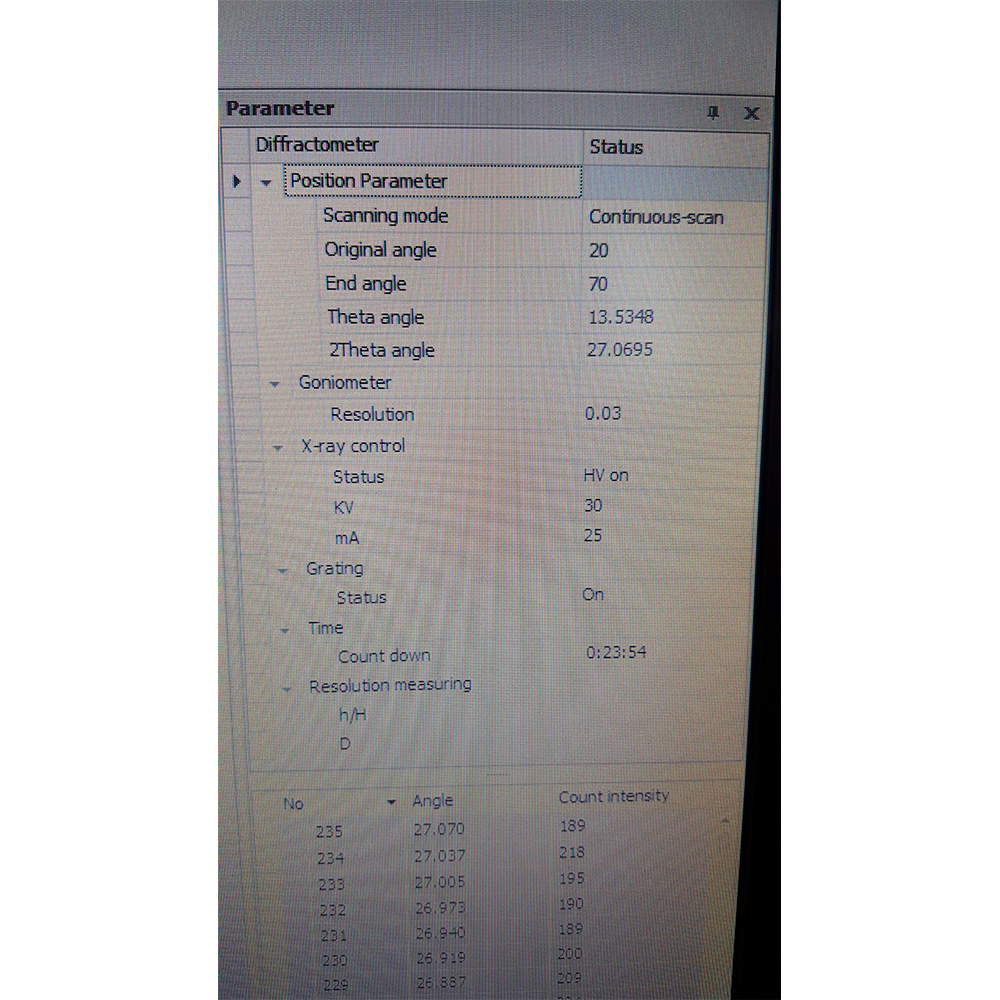

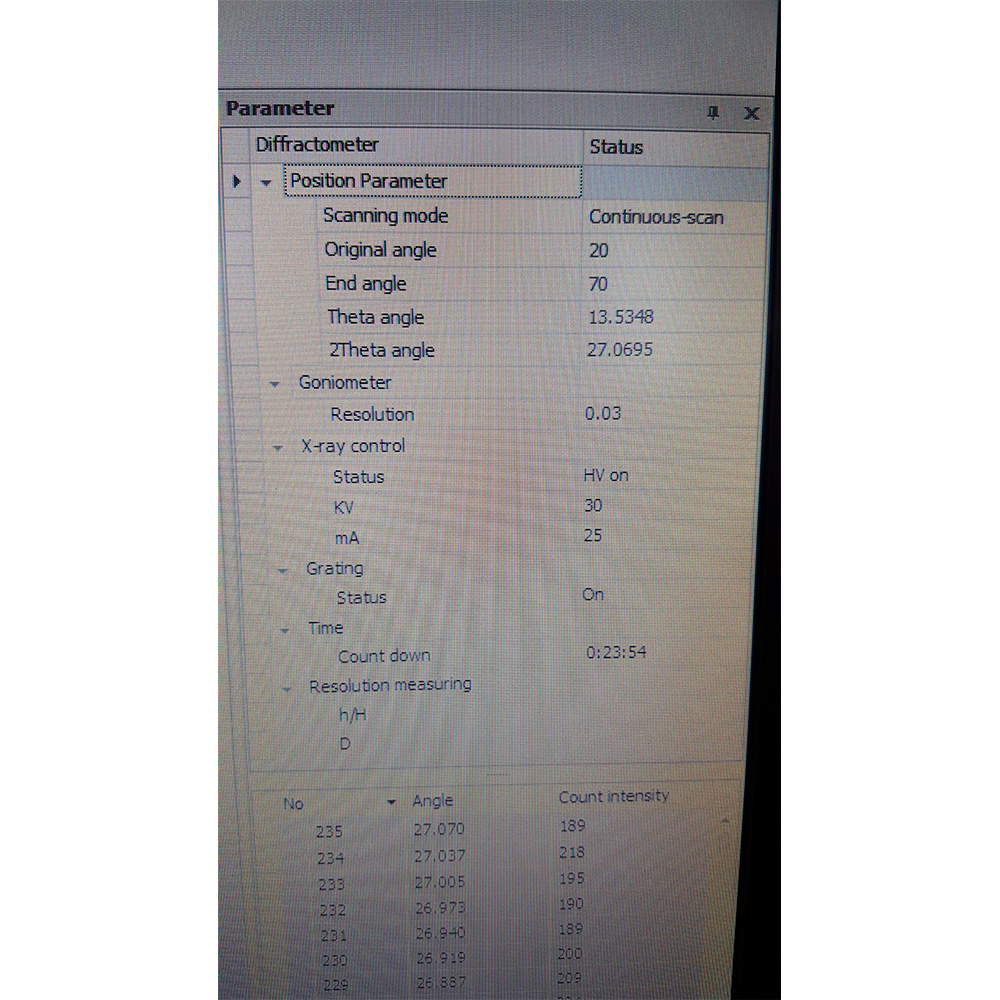

7. On-line control software

The on-line control software can order the XRD system to do continuous scanning or step

scanning and data acquisition. The software can process the general diffraction data and manage the disk file. Data processing including peak seeking (automatic and manual), single peak integral intensity calculation, smoothing, peak shape amplification, multiple drawing, etc .

8. Application software (English Interface)

8.1 Operation functions:

Diffraction peak measurement, overlap scanning, net intensity measurement, timer counter, goniometer rotating, goniometer step forward and back, goniometer adjustment, 2θcalibration, tube current and tube voltage optical shutter controlling.

8.2 Data analysis and processing function:

8.2.1 Smoothing, background deduction, Kα2 Peeling, peak seeking(mark D value,θvalue, d,2θintensity, half-peak bandwidth, display all parameters and many representing methods of diffraction peak), changing sampling step, eliminating , eliminating miscellaneous peak and Interfering peak, d data and peak position correction.

8.2.2 Calculate integral area, integral breadth, half-peak bandwidth; Spectral graph comparison, map add and subtract, and map combination; Insert text at any location in the map; Two kinds of cursors (small vernier, large cursor);Multiple zoom function; Multiple coordinate modes (linear coordinates, logarithmic coordinates, square coordinates).

8.2.3 Peak amplification: user can make any multiple of any multiple of the map by the left and right keys of the mouse.

8.3 Qualitative analysis:

Automatic retrieval and manual retrieval can be performed. Automatic retrieval results include: card number, molecular formula, matching index, reliability factor, and K value. Semi-quantitative analysis and k-value analysis can be carried out.

8.4 Quantitative analysis:

The absorption coefficient of the two components is different with the standard addition method, internal standard method and N component absorption coefficient.

8.5 The crystallinity of the sub-peak method is calculated

The partial peak process can directly change the parameters of the sub-peak by the mouse, and the difference between the fitting spectrum and the measured spectrum can be seen intuitively.

8.6 It can do refinement of cell parameters.

8.7 Index.

8.8 Diffraction data calibration:

Using standard diffraction data CARDS (1-54 groups), the original data of the measurement was deviated to correct and the instrument measurement error was eliminated.

DW-3000 XRD Working conditions

1. Host power supply, three-phase five-wire system single 220V (two sets, different phases), each phase current 20A(wire diameter 6mm²), the distribution box has at least 2 sets of air switches above C32 (including one set for computer), the distribution box is no more than 4 meters away from the location of the host;

2.The grounding line resistance ≤4 Ω;

3.The indoor temperature should be kept at 20℃±5℃

4.The power supply circuit shall not be interfered by strong electric equipment;

5.Indoor need to prevent static electricity, dust, shock, noise (less than 50 db);

6.The indoor relative temperature should be controlled below 70% (it is recommended to install air conditioner or dehumidifier);

7.Indoor should have water supply and drainage